how to perform brinell hardness test|brinell hardness test explained : purchasers Learn how to use Brinell hardness test units and testing machines to quickly and accurately assess large samples with a coarse or inhomogeneous grain structure – with knowledge and insight from Struers, the world’s leading .

WEBA Esclerose Lateral Amiotrófica (ELA) é considerada uma doença degenerativa do sistema nervoso, que acarreta paralisia motora progressiva, irreversível, de maneira limitante, sendo uma das mais temidas doenças conhecidas. O diagnóstico de ELA, em um passado recente, impunha um prognóstico reservado, com ausência de perspectivas .

{plog:ftitle_list}

Come and visit C4d3l1nhas's Linkr page to target all links and access exclusive content or products.

When measuring hardness using the Brinell method, a hardened steel or carbide ball of known diameter under a known load is forced into the material being tested. The diameter of the .

There are two methods to perform the Brinell hardness Test on the metal as follows: Standard Method. Non-Standard Method. Standard Brinell Hardness Test: Brinell Indentation Diagram. The Brinell hardness test is based on the amount of resistance that a solid material offers when it is pressed into by force. Brinell’s method produces a small depression . Basic principle and practical procedure of the Brinell hardness test - Testing machine - Test piece - Spherical indenter - Basic principle - Definition .1. Preparation of the Specimen. 2. Selection of Load and Indenter. 3. Test Machine Setup. 4. Load Application. 5. Indentation Measurement. 6. Calculation of Brinell Hardness Number. 7. Reporting the Results. Advantages and .

Learn how to use Brinell hardness test units and testing machines to quickly and accurately assess large samples with a coarse or inhomogeneous grain structure – with knowledge and insight from Struers, the world’s leading .Brinell testing of a material with different ball diameters and test forces must be conducted within the same force-diameter index ("Brinell test procedure") in order to enable direct comparison .

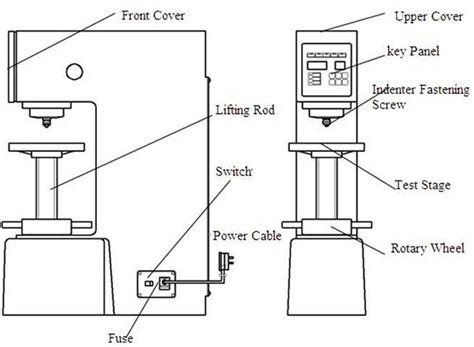

brinell hardness testing machine diagram

How to test the hardness of your material, using Brinell, Rockwell, Vickers or Leeb testing methods.1. Piling up: Indicates a low rate of hardening by deformation. 2. Sinking: Indicates the ability to work harden. The approximate tensile strength in PSI can be ascertained by multiplying the .Brinell Hardness Tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for ensuring product quality, reliability, and performance. This test reveals vital information .

II. Principle of Leeb Hardness Test. The principle of the Leeb Test depends on a combination of friction, elastic and plastic deformation. When a material is subjected to a tensile force, the deformation element (i.e., the carbide ball) glides against the material’s surface. Hardness testing can be applied to various types of materials, some of which are listed below: Metals and alloys. Ceramics. Elastomers. Polymers and plastics. Films. Rocks and minerals. Importance of Hardness .The Brinell hardness test is used for hardness testing larger samples in materials with a coarse or inhomogeneous grain structure. The Brinell hardness test (HBW) indentation leaves a relatively large impression, using a tungsten carbide ball. The size of the indent is read optically. The Brinell hardness test measures material hardness by determining the diameter of an indentation made by a hardened steel or carbide ball under a specific load. A load, typically ranging from 500 to 3,000 kgf, is applied to the material’s surface for 10-15 seconds, allowing the ball to penetrate and create an indentation. .

3.1.6 Brinell hardness scale—a designation that identifies the specific combination of ball diameter and applied force used to perform the Brinell hardness test. 3.1.7 Brinell hardness testing machine—a Brinell hardness machine used for general testing purposes.

This article explains the procedure to perform the Rockwell hardness test on metals. Rockwell Hardness Test Procedure. The Rockwell hardness test employs the principle of differential-depth method. During the test, the indenter of the equipment is forced to make a residual depth on the test specimen.The Brinell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials. . The Brinell hardness test is not suitable for very hard materials or hardened surface layers because the ball does not penetrate sufficiently into the material. Higher test loads are not the solution at this point, as this leads to deformation of the carbide ball. The flattening of the ball results in a larger indentation diameter and thus .The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell formula).To calculate the surface area of the residual ball indentation, the arithmetic mean d of the two perpendicular diagonals d1 and d2 (in mm) is .

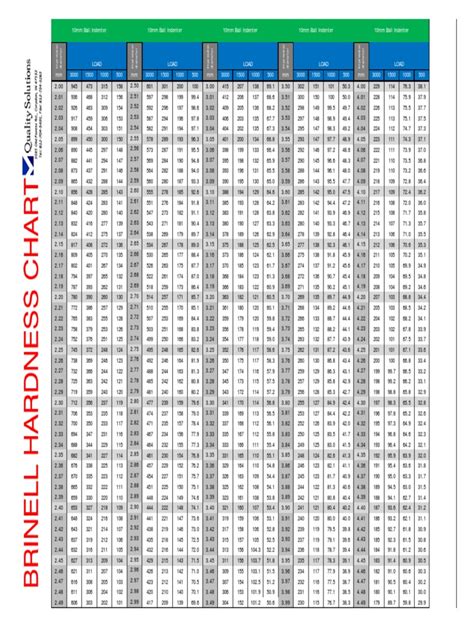

A chart is then used to convert the averaged diameter measurement to a Brinell hardness number. Test forces range from 500 to 3000 kgf. A Brinell hardness result measures the permanent width of indentation produced by a carbide indenter applied to a test specimen at a given load, for a given length of time.Proposed by Swedish engineer Johan August Brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy.The large size of indentation and possible damage to test-piece limits its usefulness. However, it also had the useful feature that the hardness value divided by two gave the approximate UTS in ksi for steels.

Concluding a hardness test using a popular method like the Brinell hardness test requires measuring the indentation left on the material surface by the load applied. Though several other hardness testing methods are available, the Brinell hardness test and how to read and represent its values are why we’ve written this guide.V. Brinell Hardness Test Procedure/ How to Perform a Brinell Hardness Test? The formula for calculating the Vickers hardness value is as follows: Vickers Hardness = (Depth of Indentation / 3.2) x Kg/mm². Where: Vickers Hardness Value = indenter depth / 3.2 = Micro-indentation of the specimen / Total micro-indentation of the specimen The Brinell hardness test in a nutshell. Determining material hardness by measuring the diameter of the resulting indentations using a carbide ball or hardened steel is known as Brinell hardness test. For example, a ball .In the Brinell hardness test, an optical method, the size of indentation left by the indenter is measured. In contrast to the likewise optical Vickers method,which involves a pyramid-shaped indenter being pressed into a specimen, the Brinell method uses a spherical indenter.

Standard Brinell hardness test: In this test, a load of 500 to 3000 kg is applied to the surface of the material for 10 to 30 seconds, depending on the hardness of the material. Micro Brinell hardness test: In this test, a load of less than 1 kg .

The Rockwell Hardness Test is the most accurate method of measuring the hardness of a material, and it is easier to perform than the Brinell or Vickers tests.01 II. Theory and Principle of the Rockwell Hardness Test In the Brinell hardness test, we use a small ball (the indentor) made of tungsten carbide or steel to penetrate the material's surface, leaving a hemispherical indent. From the load/pressure on the indentor and the diameter of the hole it makes on the material surface, we can calculate its Brinell hardness number. .

For a general demonstration of the Brinell hardness test, please refer to the video below: The adoption of Brinell hardness tests are useful for several reasons. With metallic materials, a measurement of the indentation hardness can shed insight on the materials’ tensile strength, wear resistance, and ductility, as these may correlate with .An alternative method is the Brinell hardness test, which uses a hardened steel (or tungsten carbide) ball indenter with a diameter D of, usually, 10 mm.This is applied under a load P of 500–3000 kg applied for 10–30 s.The diameter of the circular indentation d is measured in millimetres. The hardness number, (HB) is calculated using the following equation:

Brinell Hardness Test. The Brinell hardness test entails measuring the diameter of indentation caused by a constant concentrated force applied by a steel or carbide spherical indenter on a test specimen. The steel ball indenter is first placed in contact with the material before a constant force is applied and maintained for a 10 to 15 second duration, .

Brinell hardness test is a method of measuring the hardness of metallic materials which is defined in the ASTM E10 standards. It is used to gauge the hardness and toughness of a material by measuring the depth of an indent left by an indenter on the test piece when it is compressed with a specified load. The Brinell method was developed by the .

1.5 At the time the Brinell hardness test was developed, the force levels were specified in units of kilograms-force (kgf). Although this standard specifies the unit of force in the International System of Units (SI) as the Newton (N), because of the historical precedent and continued common usage of kgf units, force values in kgf units are provided for information .Brinell Hardness Test. The Brinell test was devised by a Swedish researcher at the beginning of the 20th century. The test comprises forcing a hardened steel ball indentor into the surface of the sample using a standard load as shown in Fig.1(a). The diameter/load ratio is selected to provide an impression of an acceptable diameter.Application of Brinell Hardness Test in Various Industries. The Brinell Hardness Test finds extensive application across diverse industries, playing a crucial role in assessing material hardness and ensuring the quality and reliability of products. . They perform hardness testing on a wide range of materials, providing valuable data and .

brinell hardness testing charts

WEBO site de apostas online Blaze oferece o melhor que há no mundo dos jogos de cassino online. Visite o nosso site e desfrute dos jogos da crash, double, slots, e muitos outros clássicos jogos de cassino agora. . Wild Trucks. Habanero. jogos recomendados. Ver Todos. Entre. Blaze Originals. Fortune Double. Entre. PG Soft. Fortune Dragon. Entre .

how to perform brinell hardness test|brinell hardness test explained